Omar Abi Jomaa

Mechanical Engineer

BSc. Mechanical engineering

MSc. Industrial engineering

Reach out!

Who i am

About Me

I am a licensed mechanical engineer with 14 years of experience in the industry. I've worked on a wide range of projects, from residential, commercial, medical to mixed-use developments. My goal is to study, research/review designs and supervise/manage projects that will deliver a state of the art performance and will be utilized by many generations to come.

2019- 2023

National Health Laboratories - Mesaimeer Qatar

40,000 sqm of mixed labs utilities

Prepared and delivered effective oral presentations to clients explaining new proposed systems.

Conducted weekly mechanical coordination meetings to attend to critical path tasks and resolving it.

Advised and briefed the Project Manager of all technical aspects of the mechanical services that may affect construction progress and hinder the work on site and finding immediate solutions for it.

Reviewed the contractor’s installation method of statements and ensure proper implementation on site.

Testing & commissioning all mechanical systems in the project.

§

senior Mechanical Engineer

Monitored all mechanical and biomedical related operations at site as per approved drawings and method of statement. As well as reviewing mechanical design to meet the authorities’ regulations and specifications.

Reviewing all materials, shop drawings and attending inspections.

Provided technical solutions to staff, supervisors, inspectors, and service providers, regarding installation and maintenance of mechanical system related to labs & hygienic areas.

Relevant Experience

2017 - 2018

Le Mirage Icon tower - Bin Mahmoud Qatar

4 towers, 7 floor each

Monitored the work of the contractor after being assigned as a third party consultant to report and provide solution for the incomplete mechanical systems in the project.

Provided full reports on daily basis for the client to follow up on the progress.

Daily coordination meeting with the contractor and project consultant to discuss the optimized ways to tackle the challenges demonstrated in the project.

senior Mechanical Engineer

Investigating a serious water supply complication that required us to study the water quality & propose an automatic dosing system to clean the available water by coordinating with many water specialists.

Testing and commissioning all ventilation and fire fighting systems in the project to ensure proper functionality and avoid any malfunction that could put tenants at risk.

Relevant Experience

2014 - 2017

DAMAC The Piazza Project Lusail

A cluster of 14 buildings

Reviewing Materials , conducting inspection & Testing and commissioning of systems such:

Firefighting system: Pumps, valves, Control panels, hose reels, sprinklers, Detectors, CO sensors.

Chilled water system: Pumps, Heat exchanger, control panels, Variable Frequency Drives, BTU meters

senior Mechanical Engineer

ACMV system: Air Handling Units, Fan Coil Units, Extract and pressurization fans, Valves, Grills Diffusers, volume and fire dampers

Water Supply & Drainage: Booster, submersible and lift pumps, PRV, Pressure vessels, valves.

Gas System: PRMS (Pressure regulating station), Shutoff valves, solenoid valves, sensors, gas meters.

Swimming pools: Filtration pumps, chemical dosing Pumps, Pressure vessels, Nozzles, control panels.

Relevant Experience

2012 - 2014

Fox hills 17 residential buildings in Lusail

Condominium complex

Reviewing & Approving Shop drawings for all mechanical services.

Reviewing & Approving ESP calculations for fans , Hydraulic calculations for firefighting systems , Head loss for Chilled water and booster pumps , Heat load calculation for fan coil units and Air handling units.

Conducting MEP weekly meeting with the main contractor and all subcontractors and ensuring all activities are as per the project schedule.

senior mechanical engineer

-Meeting supplier and conducting factory visits and factory test for long lead items to ensure quality and durability of items (Italy, Germany, turkey, Dubai.

Inspections for all mechanical services on site to ensure conformity with international codes such as NFPA , AHSHRAE , SMACNA , ASHGAL , QCDD.

Testing and commissioning of all mechanical services in the projects (firefighting, fire alarm, district cooling systems, ACMV, Gas systems (SNG), Drainage systems, water supply.

Following up with Civil defense and MARAFEQ during design stage to attain all approvals (DC2)

Relevant Experience

2009 - 2010

Mechanical Inspector engineer

The Pearl Qatar - Infrastructure package

400 hectares built around 3 major Precincts

Inspecting and testing pneumatic Solid Waste Collection System (Air Valves, Discharge, Valves, Pipes, Control panels, Inspection Openings, Cycloids, MCC.

Inspecting and testing pumping Stations: MCCs (Motor Control Centers), PLCs, VFDs, Pumps(Submersible, Filter, Circulation) ,Filters, Valves, Pressure Transmitters, Level Switches, Chlorinators, Flow-meters, Salinity and Flood Sensors.

Inspecting and testing restaurant & Office Buildings, Document Control Building, and Main Gate Space Frame (FF/FA/ACMV).

Inspecting and testing double Containment Gas pipes with gas Meters, control panels, and Valve boxes)

Inspecting and testing sewage water (Storm water pipes, Irrigation pipes, and Grease Interceptors).

Inspecting and testing water features (Pumps, Nozzles, Lights, pipes, Filter Systems, Flow Calculations, Vibration, Bearing Pads, Valves, and flow meters.

2010 - 2011

Mechanical Inspector Engineer

The Pearl Qatar - Viva Bahriyah Tower 29

Two connected towers of 24 floors each

Inspecting all mechanical services inside tower, town houses and Risers including.;

Chilled water pipes, valve packages, Drainage systems, BTU metes for chilled water, HVAC systems FAD, TED, SAD, RAD and Fresh/ exhaust air fans, Fire Fighting pipes, pumps, sprinkles, fire Extinguisher/blankets, water heaters, bath tubes and valve packages.

2010 - 2011

Mechanical Inspector Engineer

The Pearl Qatar Medina Centrale

Medina Centrale precinct is a town square

Reviewing & approving Material submittals, design and calculation responding to site clarifications, Shop drawings, Method statements, and Test Procedures.

Monthly Progress Report Preparation, Coordination Meetings, Following Contractual Issues and Responsibilities.

Site Supervision, Site Instructions and Clearances, Material Installation, site testing and commissioning.

Education, Certification, Awards, and Others Projects

Balamand University - Lebanon

Bachelor of Science in Mechanical Engineering, 2008

I was an active member of the engineering club and demonstrated a great performance with the workshops provided by the university.

Lebanese International University - Lebanon

Masters of Science in Industrial Engineering, 2018

I graduated and recorded the highest GPA in my batch and graduated with high honors,

and i was the president of the institute of industrial & systems Engineering club.

PMP certification preperation program

A 40 contact hours course completed, 2015

I accomplished the preparation course of project management professional after 40 contact hours. I learned from experts in the industry and earned my certificate

AMCA - Air movement & Control Association International

A 5 professional development hours course completed, 2016

I accomplished a course on system design for tunnel smoke exhaust, avoiding fan system effect, introducing the fan efficiency index, sizing and selection of AMCA- certified sand louvers and CFD analysis.

National workshop on water foot print (iso 14046)

A 2 day condensed training program, 2018

During these 2 days i went through a condensed training on ISO 14046 with a

program supervised by Sweden specialist, international

experts and trainers.

Graduation with honor ( cum laude)

Institute of industrial & system Engineering (IISE), 2017

I was elected the president of the institute of industrial & system Engineering (IISE)- LIU branch for 2 consecutive years (2017 & 2018) and graduated that year with the highest GPA in my batch and was awarded a notation from the Dean of industrial engineering department.

Skills & Proficiencies

Engineering software

AutoCad Sketch

Strong background in creating 2D drawings

Computer-Aided Design (CAD)

Moderate experience with 3D Modeling Design

Carrier's Hourly Analysis Program (HAP)

Familiar with estimating loads, simulating energy use & calculating energy cost

other skills

Power Point

Professional presentation & Editing

MATLAB

Basic programing

Microsoft office

Documents, spreadsheets, formulas

Selected Projects

NATIONAL HEALTH LABORATORIES - MESAIMEER, QATAR

Ashghal is constructing the National Laboratory Building at an area of 29,000 m2 in Mesaimeer Area, with 4 levels to provide several services such as food safety labs, infectious disease labs, specialized labs, and emergency section for national and environmental disasters.

THE PEARL PROJECT- QATAR

The Pearl-Qatar in Doha, Qatar, is an artificial island spanning nearly four square kilometers. It is the first land in Qatar to be available for freehold ownership by foreign nationals. As of 2018, there are 27,000 residents.

Selected Projects

MEDINA CENTRALE, THE PEARL, QATAR

Medina Centrale precinct is a town square inspired by the charming ambience of the Mediterranean. With a mixture of public plazas, gardens, terraces, canopies and piazza. It is a residential destination that brings together the unique qualities and charm of the island.

Le Mirage Icon, Doha

Set in Bin Mahmoud, the heart of Doha’s bustling commercial center, Le Mirage Icon is an exclusive residential complex of fully furnished and tastefully appointed two-bedroom apartments..

Selected Projects

The Piazza Lusail, QATAR

"The Piazza, A cluster of 14 buildings creates a unique community with superb work, leisure and residential offerings. Striking architectural cues are combined with world-class design and finishing, along with a wealth of high-end amenities to create a well-balanced lifestyle near the waterfront.

17 BUILDINGS FOX HILLS LUSAIL, QATAR

The Fox Hills Developments are a series of three residential developments located in the Fox Hills South District of the new Lusail City Development. These luxury developments offer a choice of 1-3 bedroom apartment units in a prime location, close to Doha’s up-and-coming business capital for the perfect commute.

Experienced Mechanical Systems

AIR COOLED CHILLERS (RTAC)

Air cooled chillers installed with 1093 KW in capacity with 4 silent helical-rotary compressor

that is semi-hermetic, and The evaporator is a tube-in-shell heat exchanger design, each unit has two refrigerant circuits, with one or two helical-rotary

compressors per circuit.

FRESH AIR HANDLING UNIT (FAHU)

Fresh air handling units with capacities around 12,000 l/s and 200 tons of cooling with fine and HEPA filters and all coils are protected with UV lights and equipped with heat pipe of aluminum fin and stainless steel casing.

Experienced Mechanical Systems

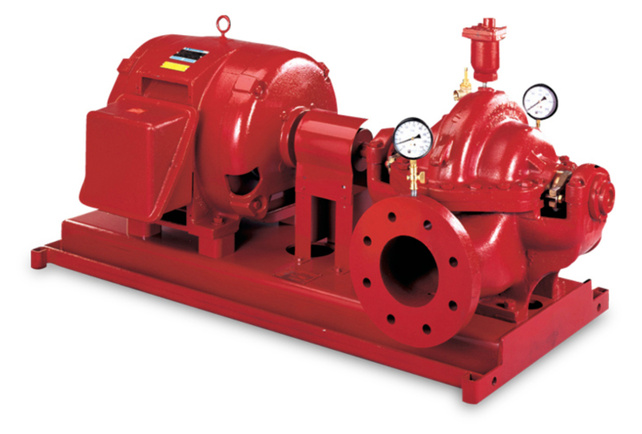

Horizontal split case fire fighting Pump

A 500 gpm horizontal split case fire fighting pump system (Electrical, Diesel, Jockey) @ 100 Psi with all its accessories and fire suppression system including sprinklers, fire hose reels, FM200 and extinguishers.

Double interlock Pre-action system

Pre-action sprinkler systems, are used to protect areas where water can damage the installed system and for that wet sprinklers or piping systems are avoided. These are a middle ground between dry and wet fire protection systems.

Experienced Mechanical Systems

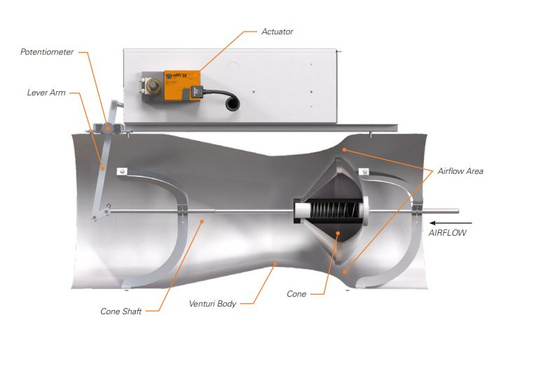

Fast Act Variable air Volume (Venturi Valve)

Venturi Valve is designed specifically for room pressure control and laboratory applications. Paired with the maintenance-free, high accuracy, Controls Pressure Transducer (PTX) and an actuator, the VFX achieves precise airflow measurement and control for critical environments.

Deionized Water Systems

Certain projects including labs or hospitals require a very specific quality of water due to accurate experiments and for that the deionized system including reverse osmosis and filters are used to provide such kind of water.

Experienced Mechanical Systems

Waste Management Collection System 1/2

The waste inlets connect to an underground pipe network. The emptying cycle is done at pre-programed times or when the units are full. The waste is transported at 70kph speed, using negative airflow that sucks the bags to a remote collection station

Waste Management Collection System 2/2

Emptying takes only minutes per waste stream. Being underground makes the Envac system resilient against extreme weather events and with smart automation, it is reliable even in times of societal pressure. The collection station can be located as far away as 2 km from the central urban area, reducing the impact of heavy traffic, such as noise, air pollution, and traffic jams.

Experienced Mechanical Systems

Water features and Pools

Water features including floating pumps and dancing nozzles, as well as swimming pools with vacuum, over flow, supply and return networks with a state of the art finish giving the feature an outstanding esthetic view.

Mechanical Hydraulic and Chemical System

Mechanical Rooms serving wellness, pools, water features and water treatment including non-chlorine systems, energy efficient systems to fully automatic dosing control.

Experienced Mechanical Systems

Biosafety cabinets and Fume Hoods

As a big part of the national labs, the biosafety and fume hoods required an adequate attention when it comes to providing mechanical provisions such as cold, cooled, deionized and soft water as well as automated exhaust that will maintain safety and functionality of the systems.

Laboratory Caseworks

Labs include a specific kind of furniture called casework that allows scientists to works and perform the required experiments, in which mechanical provisions such as LPG serving points and dilution trap tanks shall be provided to enhance the processes and tasks.

Experienced Mechanical Systems

Axial and Jet Fans

Different types of fans are used in projects such as make up, extract, smoke and jet fans. These fans are calculated and installed after providing a proper CFD analysis to determine the locations and orientations of each fan.

Automatic Opening Vents

These types of vents are installed to ensure proper evacuation of smoke in cases of fire, and they are usually integrated with the fire alarm system as well as the BMS to ensure proper monitoring and immediate reaction once needed.

Experienced Mechanical Systems

Waste Neutralization system

Due to the availability of highly acidic or basic waste drain in some of the projects, a neutralization system is introduced to regulate the PH of the waste drain prior to discharging it to the municipality drainage network. The system include dosing pumps, automatic stirrer, chemical resistance valves and an electrical panel to control it.

Corrosion resistance exhaust lab fans

Some of the air required to be exhausted might contain corrosive gases, in such case special kind of fans shall be used that are made of non ferrous materials. Such kind of fans shall have their motors installed away from the airstream.

Connect with me

Omar Abi Jomaa

omarabijomaa@hotmail.com

omarabijomaa@gmail.com

00974-50647155

00961-71585990

DOHA - QATAR

Find my linkedin link here :